HTML Preview Product Failure Analysis page number 1.

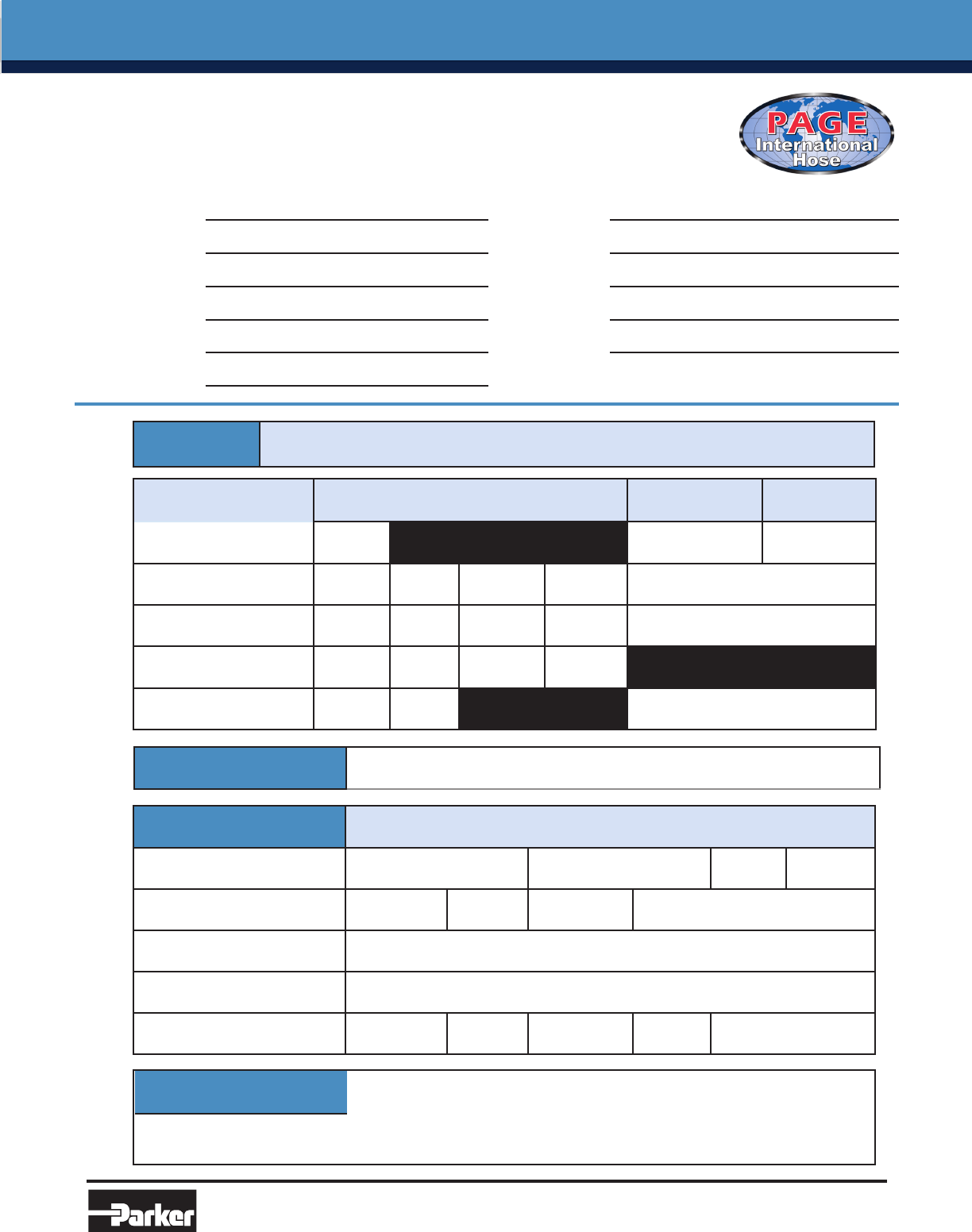

PRODUCT FAILURE ANALYSIS

Fax completed form to 888.293.2667

Media Transferred: Time in service:

Flow Rate:

(Gallons per minute)

Velocity:

(Feet per second):

Working Pressure:

(minimum) (maximum)

Constant or Impulse?

Working Temp.:

(minimum) (maximum)

Constant or Cyclic?

Vacuum Amount:

(minimum) (maximum)

Bends of Movement:

amount

Static or Dynamic?

Special Conditions

Cleaning Conditions Chemical or (CIP)? Steam or (SIP)? Temp:

Atmospheric Conditions: Temp: Chemicals:

Installation/Handling

Conditions:

Remarks:

Bends of Movement:

amount

Static or Dynamic

Additional Comments

Static Dissipation

Conditions

Company: Phone:

Contact: Fax:

Address: Email:

PAGE Order #: Cust. PO #:

PAGE Part #: In-service Date

Failure mode:

Application Attach diagrams, drawings or extra information

Form #4-4.4.4 Rev E Oct 2010

©2010 Parker Hannin Corporation - all right reserved

Parker Hannifin Corporation

Parflex Division

Ft. Worth, TX 817.625.5081