HTML Preview Technical spec sheet example page number 4.

- 4 -

Typical Physical

Properties and

Performance

Characteristics

(continued)

Note: The following technical information and data should be considered representative

or typical only and should not be used for specification purposes.

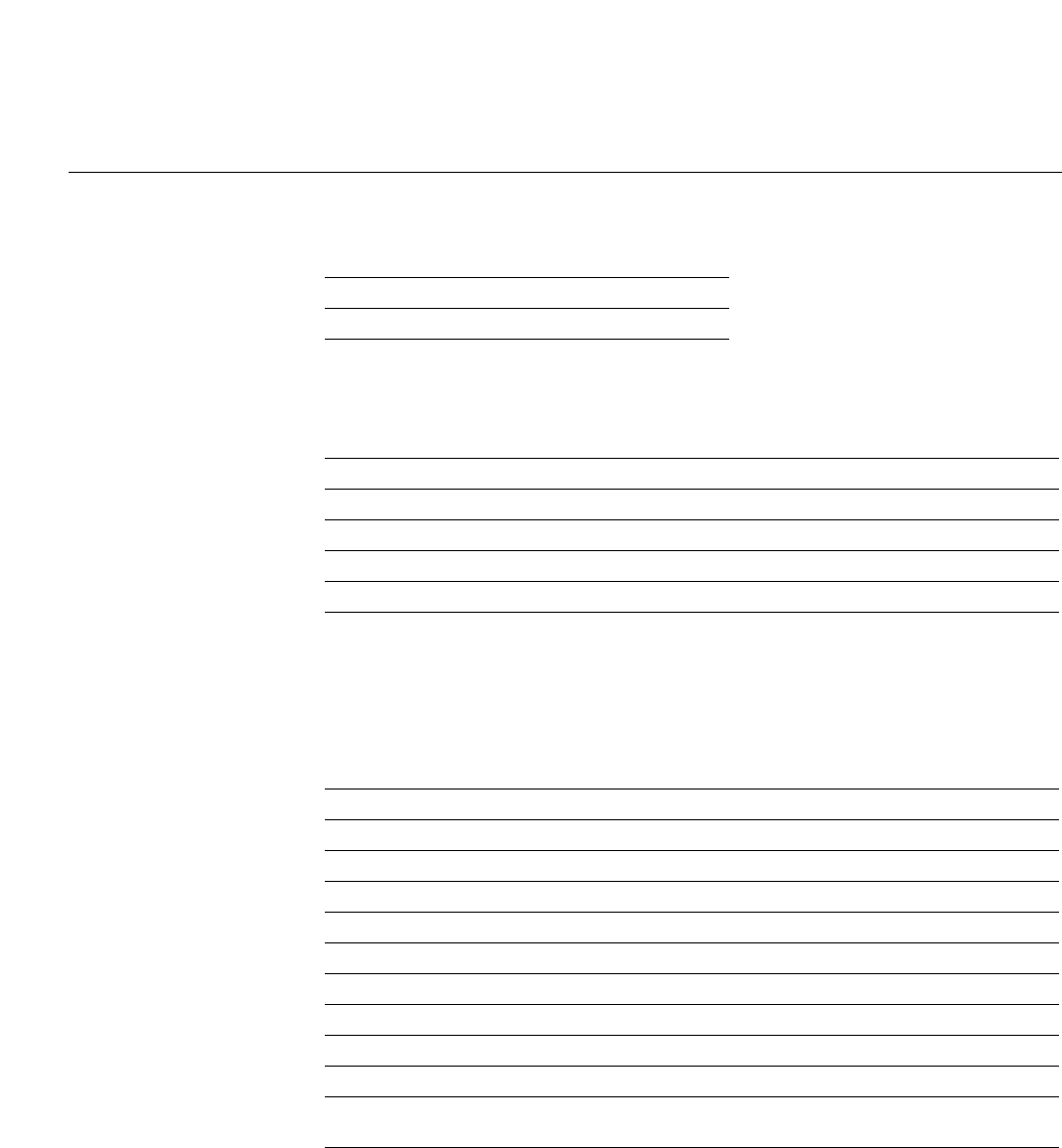

III. Relative High Temperature Operating Ranges

Short term (minutes/hours) 400°F (204°C)

Long term (days/weeks) 300°F (149°C)

IV. Static Shear

ASTM D3654 - 1" x 1" sample area - aluminum foil to stainless steel

Minutes to Failure

Temperature Load 2 mil 5 mil

70°F (21°C) 2000 grams 10,000+ 10,000+

200°F (93°C) 1000 grams 10,000+ 10,000+

350°F (177°C) 500 grams 10,000+ 10,000+

450°F (232°C) 400 grams 60 75

450°F (232°C) 200 grams 10,000+ 10,000+

V. Shelf Life of Tape in Roll Form 24 months from the manufacturing date when

stored at 70°F (21°C) and 50% relative humidity.

VI. Adhesion Retention after Immersion and Exposure (percent retention)

Control is 24 hour RT dwell on stainless steel, 2 mil al foil backing, 90° peel, 12 ipm

3M™ Adhesive 200MP

2 mil 5 mil

Control adhesion value in ounces/inch 101 oz./inch 149 oz./inch

gasoline - 1 hour RT immersion 89% 83%

MEK - 1 hour RT immersion 64% 66%

weak acid - 4 hour RT immersion 86% 86%

weak base - 4 hour RT immersion 84% 83%

oil (10W30) - 72 hour, 120°F (49°C) immersion 146% 141%

water - 100 hours, 70°F (21°C) 105% 116%

salt water (5%) - 72 hours, 70°F (21°C) 105% 93%

warm/humid - 7 days, 90°F (32°C) and 90% relative humidity 131% 101%

UV cabinet - 30 days, 70°F (21°C) 147% 93%

Temperature Cycle - *Three cycles 148% 158%

*One cycle is 4 hours, 158°F (70°C); 4 hours, -20°F (-29°C); 16 hours, 70°F (21°C)

VII. Low Service Temperature

The glass transition temperature for 3M adhesive 200MP is -31°F (-35°C). Many

applications survive below this temperature (factors affecting successful applications include:

materials being bonded, dwell at RT before cold exposure and stress below the TG [i.e.

expansion/ contraction stresses, impact]). Optimum conditions are: bonding high surface

energy materials, longer time at RT before cold exposure and little or no stress below the Tg.

6

Adhesive 200MP is not recommended for low energy plastics (polypropylene,

polyethylene, powder coated paints). For these surfaces please refer to 3M™ Adhesives

300, 350, 300LSE and 300MP. The 3M™ Adhesive 300LSE has been used more

frequently as the bond areas in applications become smaller. It offers the smooth, high

performance characteristics of the 3M adhesive 200MP with higher adhesion to plastic.

3M adhesive 300LSE is ideal for polyethylene, polypropylene, powder coated paints and

for applications where the bonded area to plastic is less than 1/2" wide.

3M

™

High Performance Adhesive Transfer Tapes with Adhesive 200MP

467MP • 468MP • 467MPF • 468MPF • 467MPR • 468MPR • 7952MP • 7955MP

7962MP • 7965MP • 9172MP • 9172PT • 9185MP • 9188 • 9667MP • 9668MP • 9676