HTML Preview Project Resource Planning page number 1.

Advanced Service Planning

Project Resource Planning (PRP) provides a

sophisticated set of planning tools for material-based,

service-only, and service-plus-material projects. PRP

plans and re-plans activities and tasks, synchronizes

dates, and performs impact analysis and simulations to

improve on-time completion.

Through the Project Management Interface application,

PRP can access Microsoft Project to enhance

scheduling, graphic displays and networking

capabilities. By associating routings and bills of

material with service items, PRP ensures that materials

and resources get to the right place at the right time.

Analyzing “What-Ifs”

Project Resource Planning offers a variety of tools for

developing “what if” scenarios and analyzing their

impact. Simulations allow you to view anticipated

changes to planned orders. Multi-level pegging

provides full visibility to all items in a bill of material.

Impact Analysis displays the imploded, multi-level

impact of lead time delays. PRP reconciles dates

between contracts, projects and orders and displays

mismatches. You can then synchronize dates based on

multiple options to determine the best plan for your

requirements.

Workbench Utility

A workbench provides a single point of entry for

developing and modifying plans and accessing

necessary data files. This allows you to make optimal

use of resources and to respond quickly and

appropriately to scheduling changes.

Lot-for-Lot vs. SEIBAN

For cost effective purchasing and production, PRP

allows you to choose either consolidated or lot-for-lot

planning. In lot-for-lot planning, supply order quantities

are matched to demand quantities with variables such

as scrap factor taken into consideration. This structure

enables mutli-level pegging and is especially useful for

engineer-to-order and make-to-order items.

Consolidated planning in PRP is addressed by way of

SEIBAN functionality. Using SEIBAN, a unique number

is assigned to an assembly item. All component items

are then assigned the same number. Costs can be

assigned to each component item and rolled up using

SEIBAN costing.

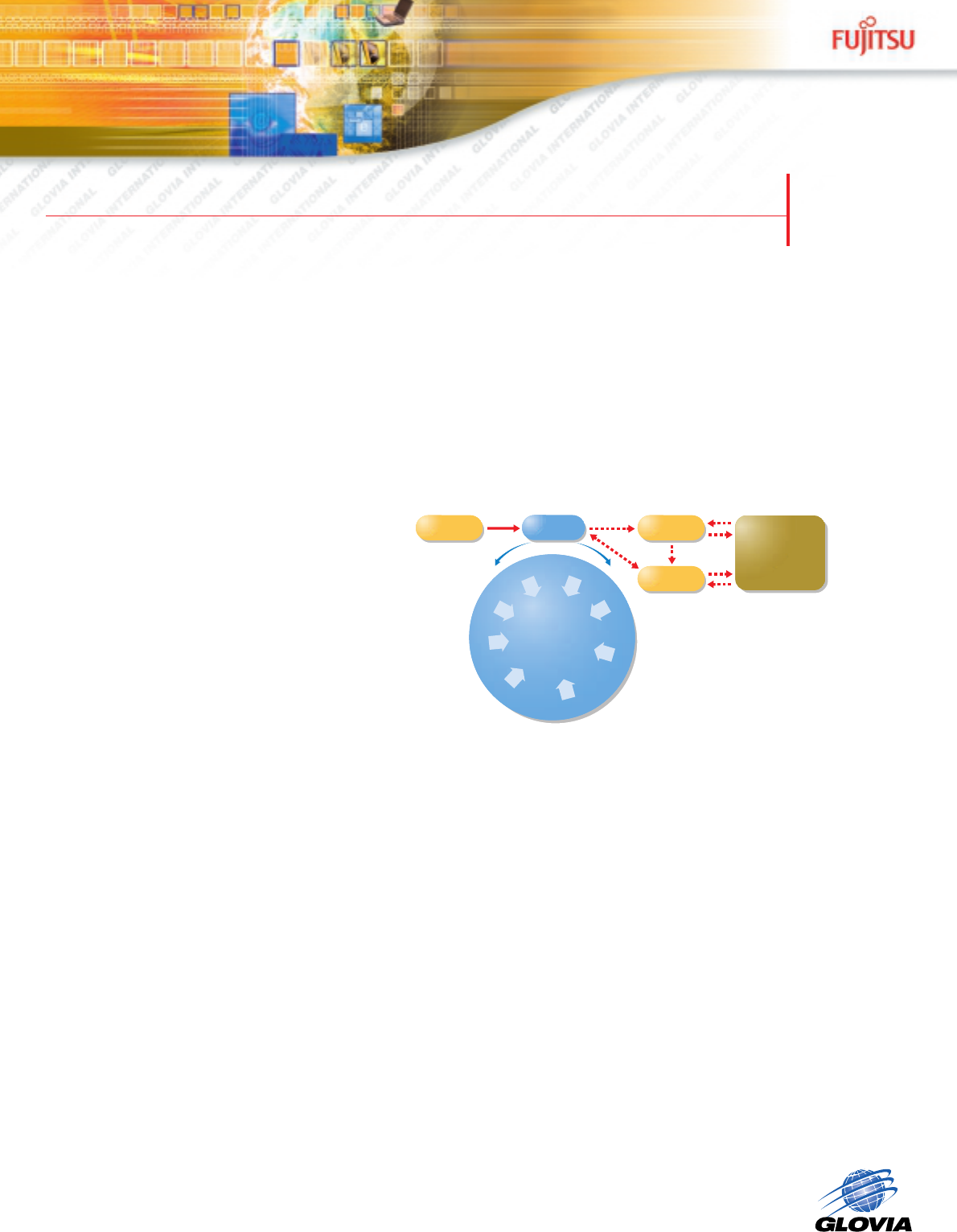

PRP Workbench Actions

The actions that can be performed on items in the

Now all of your projects including service-only and service plus material projects can have the planning visibility

needed to stay on schedule and respond quickly to change. glovia.com Project Resource Planning provides multi-

level planning tools that include an easy-to-use workbench for developing and modifying plans online. Optimize your

planning capabilities with sophisticated simulation, date synchronization, and impact analysis features that assure on-

time, on-target projects.

glovia.com Project Resource Planning enhances your ability to plan complex

projects with a rich set of features, including date synchronization, impact

analysis, and simulation tools.

Project Resource Planning

GLOVIA.COM

Manufacturing:

• Seiban

• Serial and Lot

• Outside Processing

Plan

Re-Plan

Simulation

Date Synchronization

Status

Impact Analysis

PRP

Contract Project

Work

Orders

O

R

D

E

R

C

O

N

T

R

A

C

T

P

R

O

J

E

C

T

S

E

I

B

A

N

F

I

L

T

E

R

S

M

E

S

S

A

G

E

S

S

U

P

P

L

Y

O

R

D

E

R

S

I

N

V

E

N

T

O

R

Y

The Project View of Manufacturing