HTML Preview Statistical Process Control page number 1.

Interpreting Statistical Process

Control (SPC) Charts

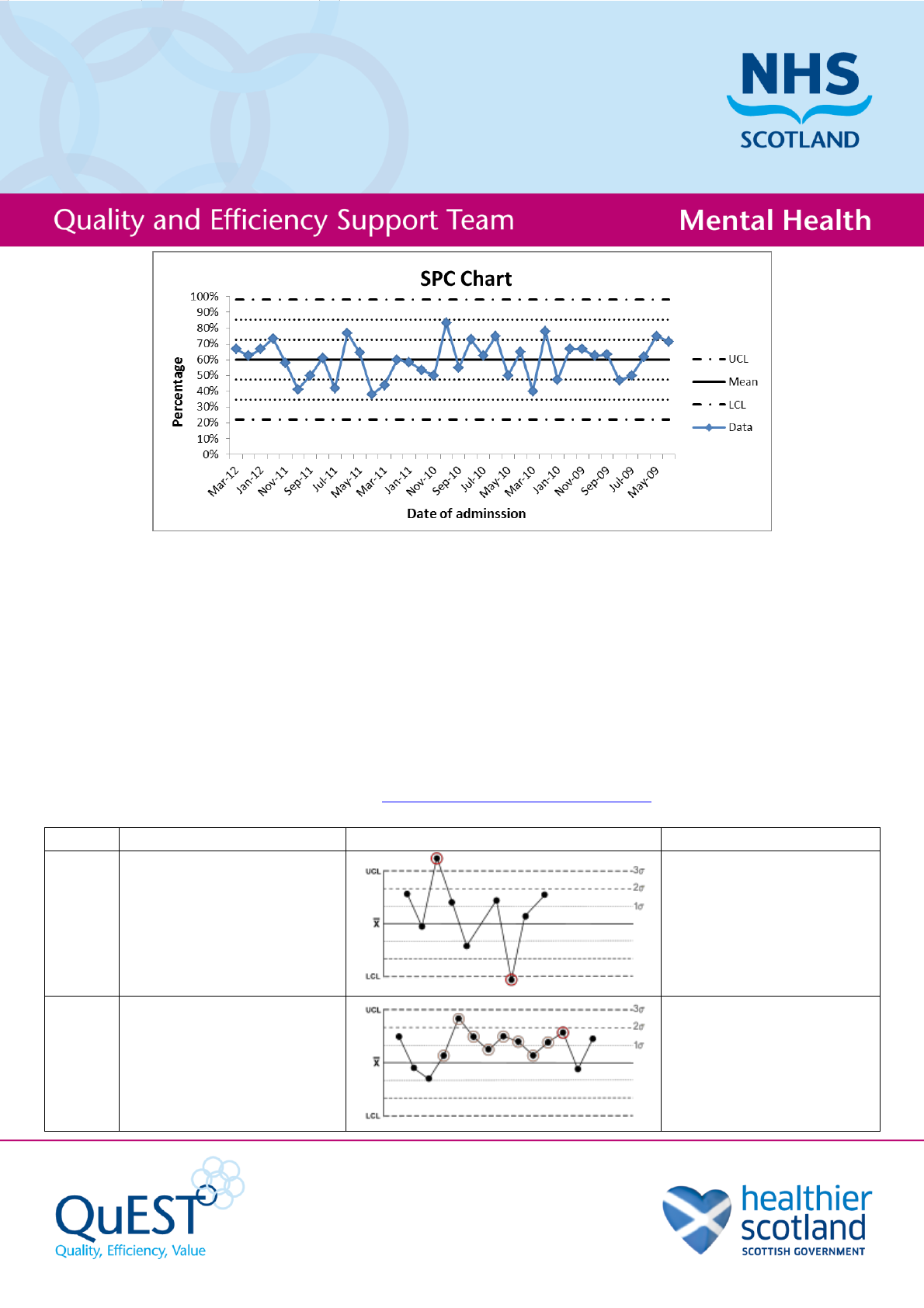

The main elements of an SPC chart are:

- The data itself, which is data in order over time, usually shown as distinct data points with lines between.

- The mean of the data.

- The upper and lower control limits (UCL and LCL), which are set depending on the type of SPC chart.

Usually these are 3 standard deviations from the mean.

Sometimes (and useful for interpretation) the chart will show thirds (1 and 2 standard deviations from the

mean) between the mean and the control limits.

Interpreting an SPC chart

There are 8 signs of special variation you should look for in an SPC chart:

(Nelson rules for interpretation taken from en.wikipedia.org/wiki/Nelson_rules)

Rule

Description

Chart Example

Problem Indicated

Rule 1

One point is more than 3

standard deviations from

the mean.

One sample (two shown in

this case) is grossly out of

control.

Rule 2

Nine (or more) points in a

row are on the same side

of the mean.

Some prolonged bias

exists.