HTML Preview Quality Control Report page number 1.

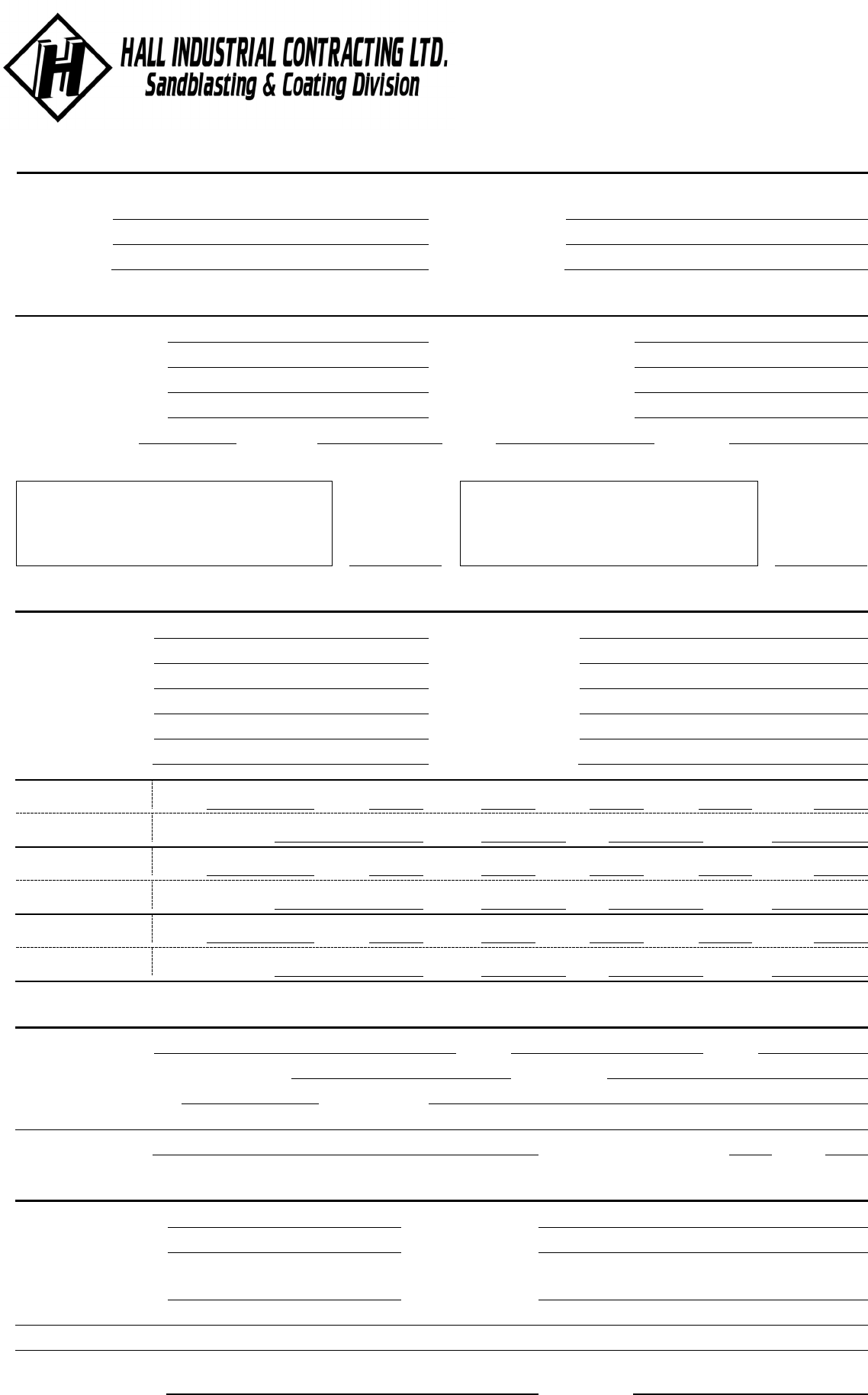

QUALITY CONTROL

REPORT

Hall’s Work Order No. _____________________

Date:

Client:

Location:

Client P.O. No.

Tank Size:

Tank No.

SURFACE PREPARATION

Pre-Cleaning:

Blast Specification:

Abrasive Media:

Surface Profile Req’d:

Nozzle Size:

Nozzle Pressure:

Air Dryer etc.:

Compressor Size:

Surface Temp:

Air Temp:

R.H.:

Dew Pt.:

TESTEX TAPE

Surface Profile

Test #1:

Surface Profile

Test #2:

COATING APPLICATION

Supplier:

Product:

Specified DFT:

# of Coats:

Base Batch #:

Colour:

Catalyst Batch #:

Thinner:

Thinner Batch #:

% Thinner Used:

Applied With:

Tip Size:

1

st

Coat Application

Date:

Time:

Surface

Temp.

Air

Temp.

R.H.:

Dew

Pt.

1

st

Coat Inspection

Instrument Used:

DFT

Min.:

DFT

Max:

DFT

Average:

2

nd

Coat Application

Date:

Time:

Surface

Temp.

Air

Temp.

R.H.:

Dew

Pt.

2

nd

Coat Inspection

Instrument Used:

DFT

Min.:

DFT

Max:

DFT

Average:

3

rd

Coat Application

Date:

Time:

Surface

Temp.

Air

Temp.

R.H.:

Dew

Pt.

3

rd

Coat Inspection

Instrument Used:

DFT

Min.:

DFT

Max:

DFT

Average:

FINAL INSPECTION

Holiday Inspected:

Date:

Time:

Inspection Instrument:

Wet Sponge:

Dry Spark:

No. of Discontinuities:

Location:

Method of Repair:

Repairs Inspected:

Yes

No

POST CURE SCHEDULE

Post Cure Required:

Heat Type Used:

Cure Temp.:

Cure Duration:

Project Complete:

Comments:

Applicators Signature:

Date: