Heat Transfer Coefficient R Value Types and Conversions

Save, fill-In The Blanks, Print, Done!

Download Heat Transfer Coefficient R Value Types and Conversions

Microsoft Word (.docx)Or select the format you want and we convert it for you for free:

- This Document Has Been Certified by a Professional

- 100% customizable

- This is a digital download (35.4 kB)

- Language: English

- We recommend downloading this file onto your computer.

How to calculate the Thermal Conductivity R-Value of material? And how to do conversions between R-Value in USA and RSI value? Download this Heat Coefficient R-Value for all material types and conversions template that will perfectly suit your needs!

Engineers, Architects and scientists regularly need advanced templates, forms, spreadsheets to perform their calculations. For example, this Heat Coefficient R Value Types and Conversions template which can save you valuable time and can help you with your research and your calculations.

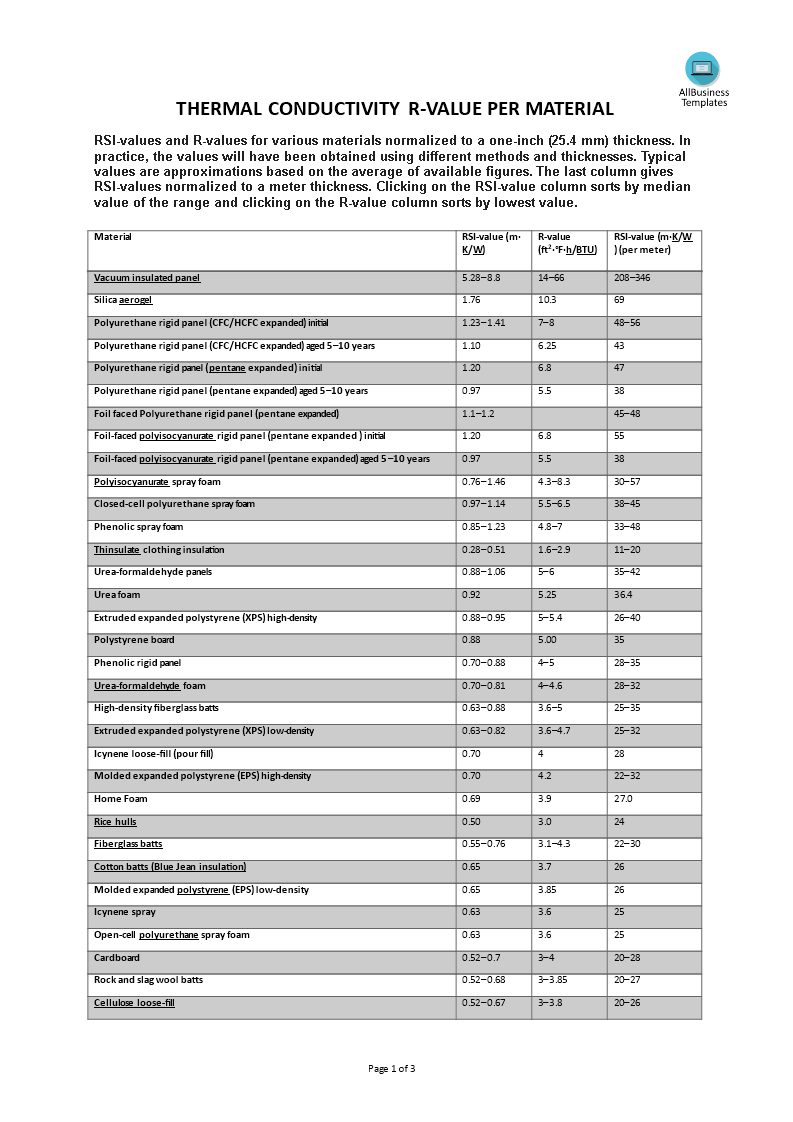

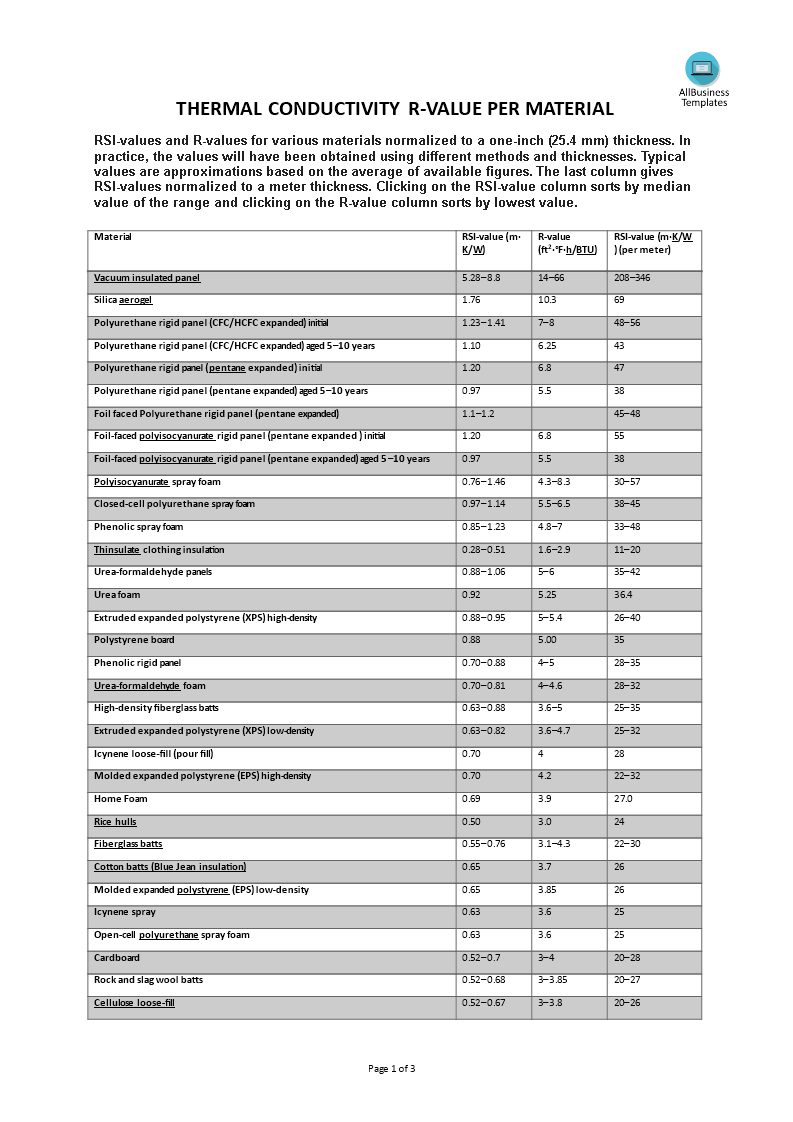

The R-Value is an imperial system unit of measurement (ft2·°F·h/BTU) and the RSI Value is a metric system unit of measurement (m2·K/W). The higher the resistance value, the slower the rate of heat transfer through the insulating material.

- Convert an RSI Value to an R-Value, multiply the RSI Value by 5.678.

- Convert an R-Value to an RSI Value, divide the R-Value by 5.678.

Try it now and let this engineering template inspire you. We certainly encourage you to use this Heat Coefficient R-Value Types and Conversions for your own activities and are confident it will fit your needs.

RSI-values and R-values for various materials normalized to a one-inch (25.4 mm) thickness. In practice, the values will have been obtained using different methods and thicknesses. Typical values are approximations based on the average of available figures. The last column gives RSI-values normalized to a meter thickness. Clicking on the RSI-value column sorts by the median value of the range and clicking on the R-value column sorts by lowest value. This Sheet contains R-values for the following building materials:

- Vacuum insulated panel

- Silica aerogel

- Polyurethane rigid panel (CFC/HCFC expanded) initial

- Polyurethane rigid panel (CFC/HCFC expanded) aged 5–10 years

- Polyurethane rigid panel (pentane expanded) initial

- Polyurethane rigid panel (pentane expanded) aged 5–10 years

- Foil-faced Polyurethane rigid panel (pentane expanded)

- Foil-faced polyisocyanurate rigid panel (pentane expanded ) initial

- Foil-faced polyisocyanurate rigid panel (pentane expanded) aged 5–10 years

- Polyisocyanurate spray foam

- Closed-cell polyurethane spray foam

- Phenolic spray foam

- Thinsulate clothing insulation

- Urea-formaldehyde panels

- Urea foam

- Extruded expanded polystyrene (XPS) high-density

- Polystyrene board

- Phenolic rigid panel

- Urea-formaldehyde foam

- High-density fiberglass batts

- Extruded expanded polystyrene (XPS) low-density

- Icynene loose-fill (pour fill)

- Molded expanded polystyrene (EPS) high-density

- Home Foam

- Rice hulls

- Fiberglass batts

- Cotton batts (Blue Jean insulation)

- Molded expanded polystyrene (EPS) low-density

- Icynene spray

- Open-cell polyurethane spray foam

- Cardboard

- Rock and slag wool batts

- Cellulose loose-fill

- Cellulose wet-spray

- Rock and slag wool loose-fill

- Fiberglass loose-fill

- Polyethylene foam

- Cementitious foam

- Perlite loose-fill

- Wood panels, such as sheathing

- Fiberglass rigid panel

- Vermiculite loose-fill

- Vermiculite

- Strawbale

- Papercrete

- Softwood (most)

- Wood chips and other loose-fill wood products

- Aerated/Cellular Concrete (5% moisture)

- Snow

- Hardwood (most)

- Brick

- Glass

- Poured concrete

- Etc.

Download this ready-to-use Heat Coefficient R-Value Types and Conversions template now!

DISCLAIMER

Nothing on this site shall be considered legal advice and no attorney-client relationship is established.

Leave a Reply. If you have any questions or remarks, feel free to post them below.

Related templates

Latest templates

Latest topics

- GDPR Compliance Templates

What do you need to become GDPR compliant? Are you looking for useful GDPR document templates to make you compliant? All these compliance documents will be available to download instantly... - Daily Report Sheets For Preschool

How do you create a kindergarten schedule or write a daily report for a preschool? Check out these preschool templates here. - Celcius To Farenheit Chart

How to Download our temperature Celsius to Fahrenheit conversion charts and streamline your temperature calculations and conversions here. - Play Money Template

Where to download cool Play Money templates? Download below our printable and customizable Play Money templates for fun or with space for your face template now! - Flyer Template

Creating strong marketing materials that support your marketing strategy, such as flyers or online promotion (banners, ads) are an important part of growing a successful business!

cheese